PRESS RELEASE: The Cat longwall system includes roof supports and a face conveyor for a 300m face, shearer and beam stage loader. The system features advanced longwall automation technology to enhance safety and production.

Delivery of the system is planned for the June quarter of 2019. The regional Cat dealer, Hastings Deering, will provide technical support for installation and commissioning of the longwall and will provide operational support going forward.

North Goonyella produces premium coking coal via a Cat longwall system, which was instrumental in achieving record production from the mine in 2017. The decision to move to a new Cat system was driven by technological advances that enable automated shearer steering and face alignment, reduced exposure of operators to dust, and less maintenance.

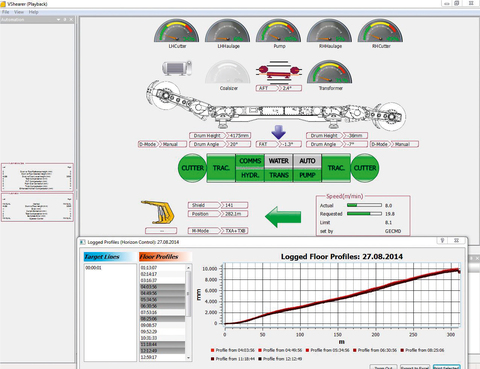

The Cat EL3000 shearer for North Goonyella will be equipped with the Cat PMC Evo-S control system, intelligent software modules and advanced measuring technology. The automation package enables the shearer to be operated by a single operator using remote control. This package includes automation logic to minimise overload situations and diagnostic tools to maximise uptime.

Software tools and sensors in the gate ends and in the shield controllers enable advanced calculations for full 3-D navigation and an accurate floor profile calculation. In total, the Cat automation package enhances safety and allows improved use of manpower, reduces coal dilution, enables faster haulage speeds, improves face management and increases life of all longwall equipment, including the face conveyor and roof supports.

Caterpillar will supply an efficient dust suppression system, designed using a holistic approach to mitigating operator dust exposure levels. With thorough understanding of dust generation processes in longwall operations and details defining the operating environment, Caterpillar engineers will design a state-of-the-art dust suppression system for North Goonyella.

Additionally, Caterpillar has developed a corrosion protection strategy to improve resistance to corrosion and to minimise maintenance activities in the North Goonyella mine environment. For example, the 153 new Cat roof supports will have specially coated rods used in the hydraulic legs, and susceptible components will be built from highly corrosion resistant materials.