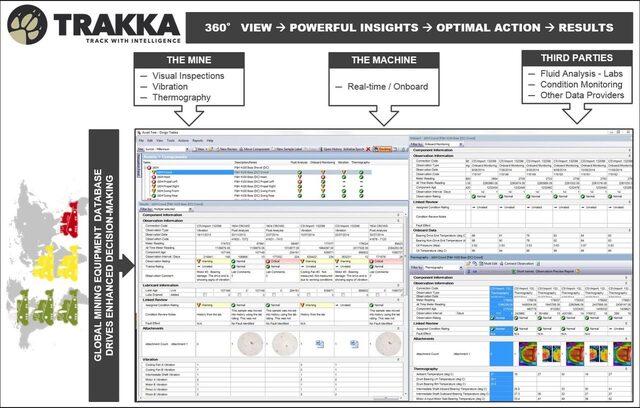

Dingo Mining's Trakka™ Predictive Maintenance Software offers the world's largest fleet health benchmarking information database. Trakka helps maintenance teams reduce operating costs by maximising the life of major components and increasing availability through the reduction of unplanned failures. It provides an easy and cost-effective way to run a predictive maintenance programme with a mine's existing resources.

A Dingo spokesperson said: "To date, we have saved our customers over US$400 million by helping them implement a systematic approach for managing the health and life of their assets. The use of cloud platforms to monitor equipment performance is not as prevalent in mining as one would expect with today's technology. Most of the cloud-based based monitoring systems that Dingo interacts with are at the large, well-resourced mines with the latest equipment."

A key benefit of Trakka is that it provides a platform for any type of mining operation to quickly and cost-effectively migrate to a centralised, cloud-based predictive maintenance system.

Many Dingo customers use Trakka at the regional and enterprise level to help monitor performance and drive improvements across the company.

Trakka manages short and long-term maintenance actions via a comprehensive prioritisation system. Maintenance tasks are created and assigned based on a composite of asset criticality, component health, and alert level severity. Depending on the nature of the identified problem and the importance of the equipment to the operation, corrective maintenance actions are assigned priority levels to minimise downtime and optimise component life.

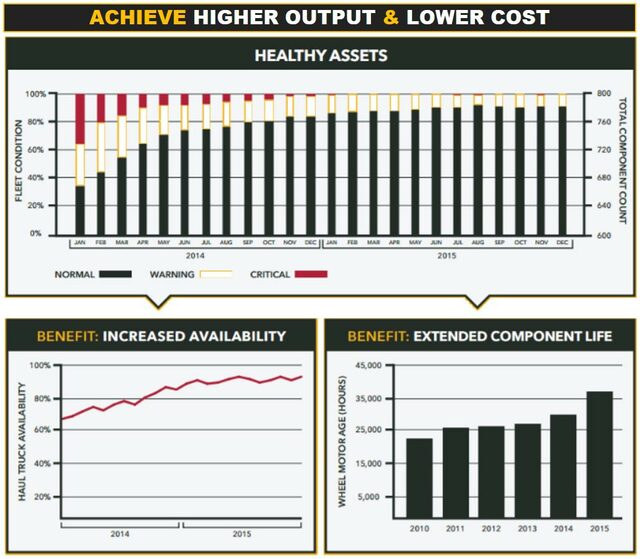

One of the ways Dingo helps customers reduce maintenance costs is by extending the life of components through its Component Life Extension program. "In our experience, most mines are using condition monitoring data to avoid potential short-term equipment failures, but they aren't focusing on overall component life achievement. The aim of the Component Life Extension program is to optimise the service life of each replaceable component through a structured maintenance management process."

"For example a coal mine in British Columbia engaged with Dingo to implement a comprehensive Condition Management program. One of the goals was to reduce maintenance costs by extending the life of their Komatsu 830E and 930E wheel motors, which can which can cost $200,000 to replace. To date, this operation has saved over $15 million through wheel motor life extension alone, and is operating many of these wheel motors for > 40,000 hours."

Trakka can be used to improve operational efficiency on any equipment that has condition data. While all of Dingo's customers use Trakka to optimise the performance of their mobile fleets, a significant number have expanded their coverage to mission critical areas such as draglines, longwalls, and processing plants.

In September, Dingo launched Trakka 4.5 to help customers truly maximise on their sensor data. By enabling customers to capture and run powerful analytics on this high-frequency data, this trailblazing version of Trakka is helping mines everywhere cut through the noise and transform an infinite sea of sensor data into actionable intelligence that drives results.

For more information on how Dingo can help your operation use its existing data to increase availability, extend equipment life, and reduce operating costs, visit our website at www.DINGO.com or send us an email at info@dingo.com.

ABOUT THIS COMPANY

Dingo

DINGO unites maintenance expertise with industry-leading technology to help mines quickly and cost-effectively implement Asset Health programmes that deliver real-world results. By continuously improving the health and performance of equipment, Dingo’s solutions increase availability, extend component life, and reduce operating costs, with typical payback of >3:1 within 12 months.

Contact us today to find out how much you can save

- E-mail: info@dingo.com

- Website: http://www.dingo.com/