PRESS RELEASE: Wenco stated that through collaborative research with major mining companies and Hitachi group companies, its latest release responds to robust interest in using data to gain visibility, insight, and control over mine operations.

David Noble, vice president, research and development at Wenco, said: "Our customers are starting to look closer at how to unlock hidden value in data. From fleet management to predictive maintenance to solutions beyond the pit, they consistently look for ways to better integrate their data. The release of System 6 brings all of these aspects of the Mine Performance Suite together, enabling customers to extract more value and context from their operations — with both real-time feedback and deeper insights from data collected."

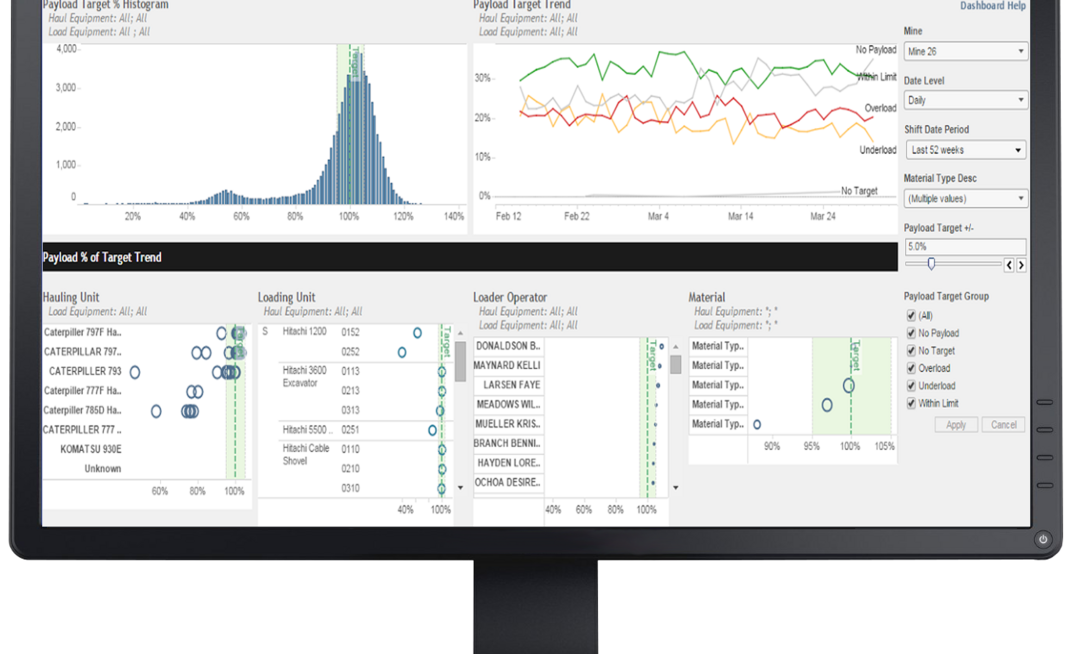

Much of this newly extracted value comes from Avoca, the business intelligence (BI) solution of System 6. This easily deployable system integrates large volumes of data from disparate mining systems, connecting data types such as geospatial coordinates, orebody quality, spotting time, machine health, shift times, weather patterns, and more. With these discrete datasets brought together, this mining BI solution can enable mines to gain efficient access to holistic views of their operations.

Noble commented: "This level of insight is a game changer for the mining industry."

The inclusion of ReadyLine, a predictive maintenance solution, in System 6 further extends this concept of data interoperability and insight. ReadyLine empowers mines to reduce unplanned downtime while extending the lifespan of equipment and decreasing the cost of machine parts. Mines use ReadyLine to monitor sensors from a broad range of OEM equipment and predict failures before they happen.

Glen Trainor, vice president, sales, support and service at Wenco, said: "We hear from customers that they need more insight to be able to better plan maintenance. Gaining predictability can significantly influence planning in the maintenance department and beyond. There has been a lot of interest in ReadyLine to expand planning capacity."

Wenco added that this renewed approach fully matches the vision of both Hitachi Construction Machinery (HCM) and Hitachi. Since HCM acquired Wenco in 2009, extensive research and development with various Hitachi group companies have concentrated on support and integration of business intelligence, preventive maintenance, and autonomous haulage systems.

Andrew Pyne, president and CEO of Wenco, said: "As a company, we are taking aim at bringing together Wenco's 30 years of mine solutions development experience and Hitachi's global leadership in systems research, data sciences, and IoT to deliver more value to customers. Mines of the future will demand even more open systems, accessible and actionable data intelligence, digitisation of processes, more predictable asset availability, and support for autonomous haulage. Wenco Mine Performance Suite Version 6 is the next step in this evolution."