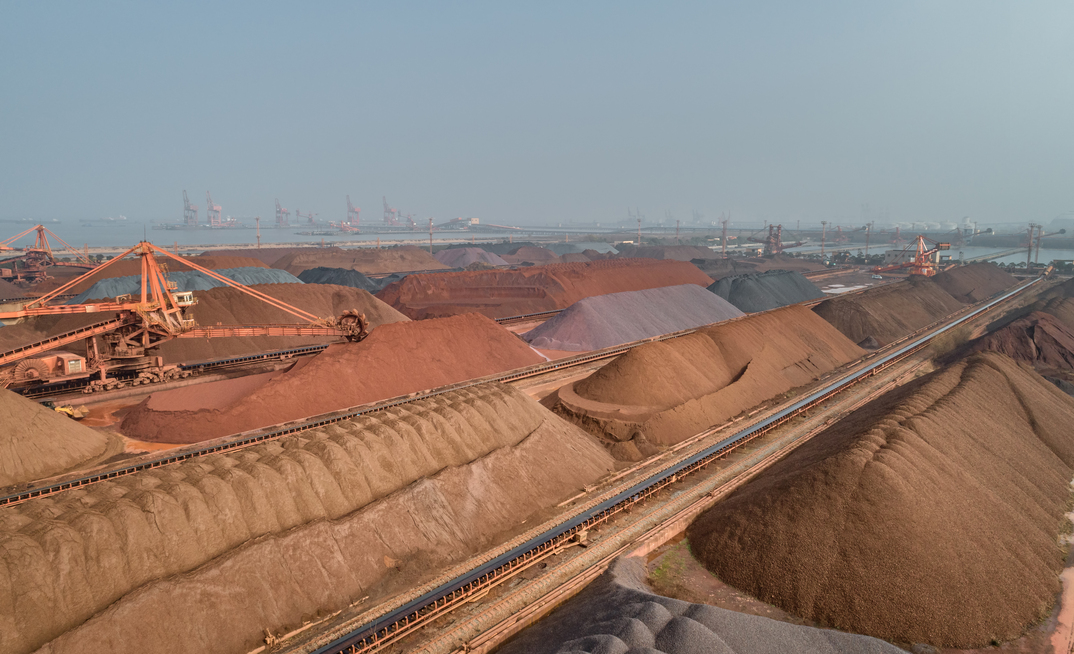

Mines are becoming increasingly interconnected with customers and logistics partners, and this means they must improve efficiency, resilience and safety as they meet demand.

In practice, this means becoming more automated, but there are substantial challenges that mine operators need to overcome as they upgrade their processes.

Mining Magazine spoke to Marcos Hillal, global product line manager, Automation and Digital at equipment supplier ABB to talk about what miners are faced with when automating, such as the effects of the pandemic and the importance of data.

According to Hillal, operators see automation as a means of boosting production and cutting waste. But some still work in silos, even within a mine's operations, and until this and other issues are resolved, the industry won't take full advantage of automation.

What are the main challenges when automating mines today?

The transition to autonomous mining operations is well underway with operators focused on boosting production, reducing costs and extending the operational lifespan of sites and in ever more extreme locations.

Mines are becoming increasingly interconnected and this is key for the automation and digitalization of key process controls.

One of the ongoing challenges is how to break down silos of operations. These are not only the traditional silos among operations technology (OT) and information technology (IT), but rather the silos that still exist within the OT area. One evident silo is among the process control team and the electrical operations team.

When we think about a motor for instance, this is an asset that ‘belongs' to both teams. From the process control perspective, the operator wants to turn it on/off, control its speed and monitor its behaviors from an individual perspective.

On the other hand, the electrical operator and maintenance team wants to manage the asset from the perspective of electrical control, monitoring how the asset is behaving, its relative consumption, and if it is healthy.

The same asset is being considered by different groups with different interests. Today, we still see plants operating process and electrical control using two different systems, across operations philosophy, look and feel and user experience.

On top of that, different systems require different engineering tools, external communications and additional maintenance to keep them running properly. The digital era demands collaboration and this type of mindset promotes the opposite.

Would you say the COVID-19 pandemic has made mining operators more likely to invest in automation or were the main drivers in place already?

Remote connectivity and operation has been an important trend in mining for some time, due to safety, declining ore resources and operational optimization. There has long been a focus on minimizing unplanned and costly downtime through predicting the upcoming maintenance needs of equipment, as well as managing labour, travel and electricity costs.

Companies have continued to invest in the digital technologies that have enabled them to align people, process, data and to achieve excellence and deliver safe, dependable, and profitable production. Remote operations are a natural extension of the digital mine and the pandemic is accelerating this move to remote-enabled solutions and making them more established.

Remote data analysis and remote service increasingly helped over the past 18 months as international travel - flights and permit windows - prevented and continue to prevent experts from physically visiting sites.

A key remote capability is augmented reality (AR), which overlays computer-generated information, data, images, video or other content onto the real-world environment through smart glasses or mixed reality devices. This enables a field service technician to share their view of a situation using the device's camera and communicate directly with an expert via on-screen annotations, chat and document sharing without that expert being on site.

On top of that, remote operations are a big trend in mining operations, especially given that good ore resources are increasingly more complex to reach or in remote locations and that attracting and retaining talent is a challenge. Bringing operations closer to urban centers and centralizing the operation of multiple sites into intelligent operations rooms helps to boost productivity and reduce the costs, by allowing better usage of data and benchmarking.

Is it easier to automate certain types of mines i.e., open pit or underground? Are there specific challenges related to both?

There is no one solution that fits all. Each mine is unique and has its own advantages and disadvantages. Open pit and underground bring different challenges, but both are equally complex projects to work on.

Taking underground mining for instance, ventilation is one of the most critical aspects to allow a proper and safe operation. Design must take into consideration all infrastructure required to run advanced applications.

Does there need to be more willingness from all stakeholders to share data to make automation projects easier in mining? If so, how can this happen? Does there need to be a regulatory body to set international data standards in the mining sector?

Data is the new gold, and without it, no one can really deliver a good automation and digital system that brings value. Although data availability and openness has improved a lot in recent years, still today we find some specific players that believe that holding data for their own use is the right strategy. Fortunately, and thanks to a push from mine operators, this is becoming less common every day.

In terms of data standards and regulation, we are seeing big improvements. In general, sharing information is improving the ability to achieve the level of digitalization that the world now requires.