The planning and management of an open pit mine is a complex and challenging task, particularly for mines that have extended mine lives. Optimization techniques can be applied to resolve any issues that arise during the mine planning process.

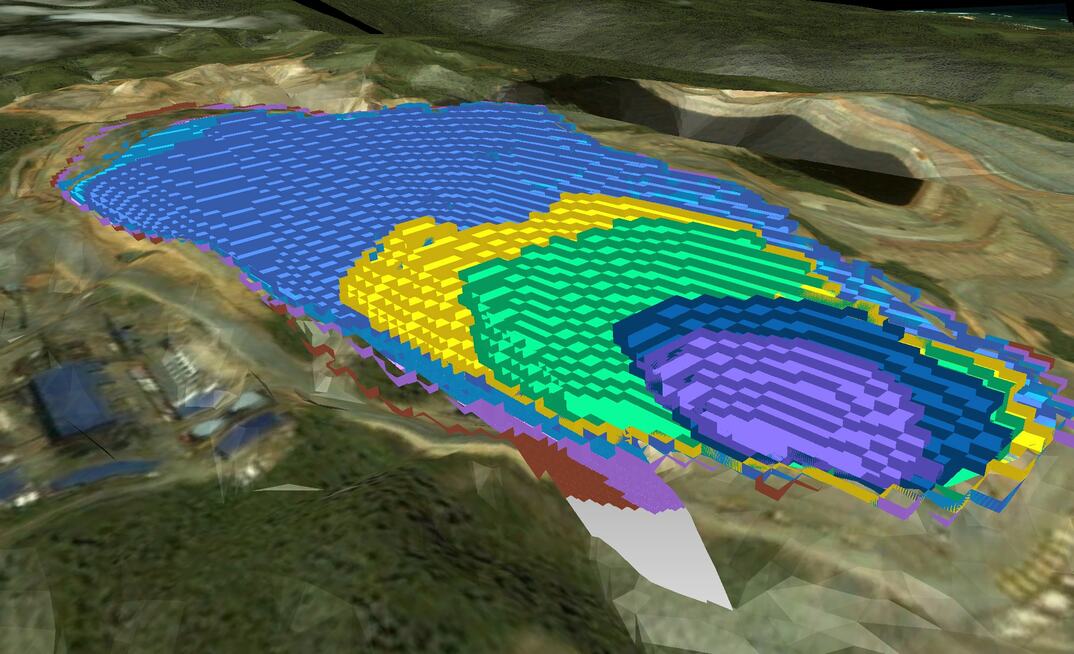

Pit optimisation is a vitally important part of the mining process and is often one of the first steps carried out by engineers in open pit mine design. A pit optimisation analysis is conducted to determine the most profitable open pit design, given a mineral resource and a set of economic and metallurgical parameters. These parameters typically consist of commodity prices, process recoveries and operating costs.

The first outcome of pit optimisation is to determine the ultimate pit that gives the highest possible undiscounted surplus between net revenue and total operating costs, without considering scheduling constraints or discounting.

Mining software plays a critical role in this process and equips mining engineers with the tools to design optimal mine plans that ensure a profitable operation. Micromine 2016 offers integrated tools for modelling, estimation, design, optimisation and scheduling and as a scalable solution provides users with the flexibility to choose the specific functionality when required.

A key differentiator for Micromine over other general mine planning software is the fact that Pit Optimisation is fully integrated into the Micromine product which means users do not need to manually import and export files to exchange data with other applications. This presents considerable efficiency gains for mine planners.

Micromine Pit Optimisation uses the industry-standard Lerchs-Grossman (LG) algorithm. Given an ore deposit represented as a block model containing ore grades or block revenues, the LG algorithm determines the pit shape by identifying the blocks that can be removed to contribute to a positive discounted surplus.

A nested pit shell analysis is then used to determine the discounted optimal pit. Nested pit shells are a sequence of ultimate pits generated by incrementing the commodity price across a range of values around the base price. The optimal pit gives the highest possible net present value, considering all operational scheduling constraints (annual mining and processing productivity), discounting and recurring capital costs.

Benefits of Micromine's Pit Optimisation module:

- Micromine's Pit Optimisation is fully integrated within Micromine, with all parameters in one place, saving time and money by eliminating the need for data exchange.

- Internal and external 32- or 64- bit engines provide the flexibility to adjust the optimiser to suit the available computing resources.

- Up to four times faster than competing applications.

- Widely regarded as being the most intuitive and easy to use pit optimisation application.

- Supports any combination of sub-blocked and rotated models and DTM surfaces.

- Input parameters for mining costs and element prices can be set up as functions instead of constants, adding greater flexibility to the optimisation process.

Micromine Product Strategy Manager Paul Hooykaas commented "Micromine provides management with an in-depth understanding of their projects so they can target prospective regions more accurately. The Pit Optimisation module is an important tool which can play a key role in determining the profitability of an open-pit mine."

"The fact that Micromine offers Pit Optimisation as a fully integrated module is a key differentiator over our competitors and provides significant efficiency gains for Micromine users. By eliminating the need for data exchange between different systems users can complete optimisation tasks much more efficiently." Hooykaas said.

The latest version of Micromine, Micromine 2016.1 SP2, addresses a number of bug fixes as well as a series of new features and enhancements including added selected annotation tools to the Exploration and Surveying modules. SP2 has been developed with the aim to enhance flexibility and functionality, improving the overall user experience.

To find out more please visit our website.

ABOUT THIS COMPANY

Micromine

MICROMINE is a leading provider of innovative software solutions that span the breadth of the mining cycle from geological exploration and data management, to resource estimation, 3D mine design, planning and production control.

CORPORATE HEAD OFFICE:

- Perth, Australia Level 2, 174 Hampden Road, Nedlands 6009, Australia

- Phone: +61 8 9423 900

- Fax: +61 8 9423 9001

- Email: marketing@micromine.com

- Web: www.micromine.com