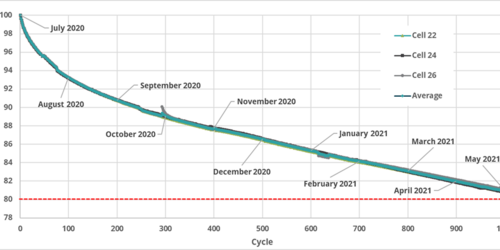

The batteries were tested at a rate of C/3, meaning three hours to charge and three hours to discharge, completing about four full cycles per day. The cathode used is of the NMC532 type. Capacity retention is calculated on the discharge capacity with respect to the first cycle.

Mason Graphite owns 100% of the rights to the Lac Guéret graphite deposit in Quebec, Canada. The company said the test results will enhance the company's ability to execute on the commercialisation of the Lac Guéret graphite.

The transformation process was developed in collaboration with the National Research Council of Canada (NRC) and Corem, a research and innovation centre in Quebec City. The purification, shaping and coating processes aim to meet the chemical and physical properties required to achieve the electrochemical performance sought by battery manufacturers, said the company.

The coated purified spherical graphite (CSPG) has been produced from a graphite concentrate from the Lac Guéret project deposit and has been replicated on a pilot scale with the involvement of Corem. The CSPG produced will be used to provide further samples for testing by potential customers during the commercialisation campaign. In December 2020, Mason Graphite reported 'remarkable' battery test results on coated spherical graphite produced at pilot scale from Lac Guéret.

Mason Graphite has expanded its workforce in order to expedite the commercialisation activities at Lac Guéret, which are expected to progress rapidly in the next few months.

Francis Fournier, president and CEO of Corem, said: "We are proud of our contribution since 2014 with Mason Graphite to the development of innovations for the extraction, purification and value-addition of the Lac Guéret project graphite. The tested coated spherical graphite was produced on a pilot scale at Corem's facilities. The processes developed in collaboration with Mason Graphite are a good example of Corem's role as a partner of the mining sector in the transition to a green economy such as the electrification of transportation."

Jean L'Heureux, chief operating officer of Mason Graphite, commented: "The accomplishment celebrated today is the result of thousands of hours of work carried out by the Mason Graphite team and by our partners. We would like to thank everyone involved for their invaluable contribution to this achievement."