Netherlands-based metal construction company Goudsmit Magnetics has unveiled an automatic rotating magnetic separator to improve the metal-free processing of lithium-ion powder for batteries.

The company said the technology filters metal particles as small as 30μm (micrometres) from lithium powder, which very often flows poorly.

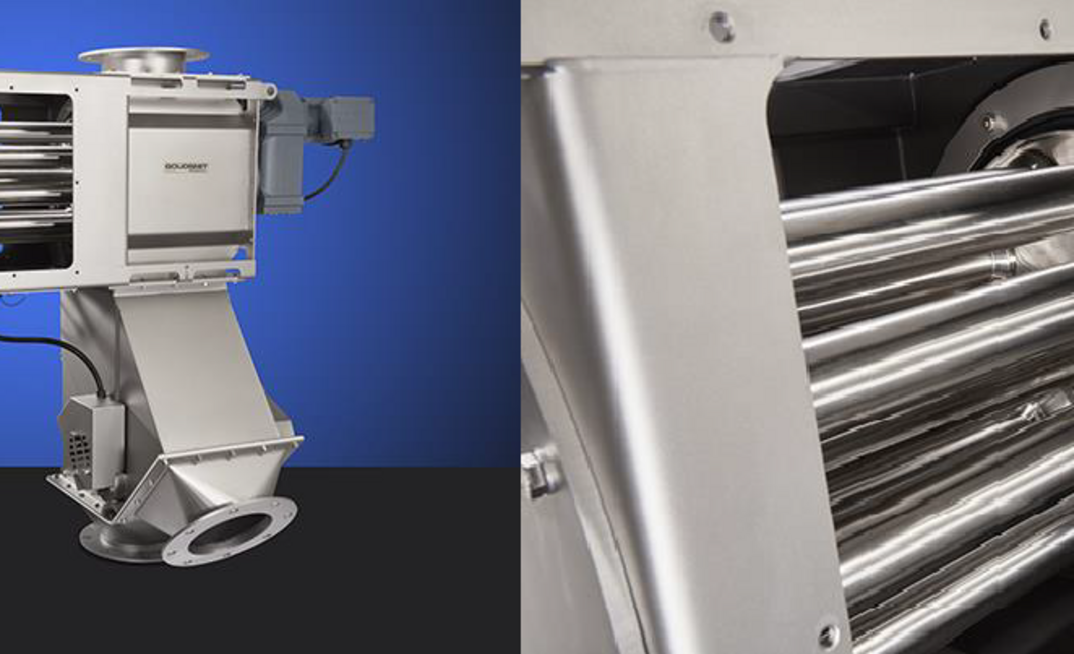

The magnetic separator contains nine rotating magnetic bars that prevent the fine powder from sticking to the bars. It then ensures that the product does not block on the bars and enables deferrization, the company explained.

Additionally, it said the magnetic separator is dust-proof and can be cleaned automatically, which helps with ensuring optimal operations.

Lithium is extracted from salt lakes such as the Salar de Atacama, Chile, where there are huge reserves of lithium-filled brine.

The powder that is processed from lithium serves as a raw material for batteries used in electric cars, laptops, mobile phones and much else.

The increasing demand for these batteries is driving up the price of raw materials extractable from mines. This applies to substances such as nickel, cadmium and lithium - known as the cathode powers - as well as to anode powers such as graphite, carbon black or silica.

Magnets play an important role in the final development of lithium batteries, both in the extraction and production phases.