KSB is proud to introduce the latest addition to the GIW pump family. The GIW® TDW pump series was developed to meet the unique requirements of tailings pond dewatering. With GIW's unmatched attention to durability and reliability, the TDW line's hydraulic design is the result of decades of experience and materials expertise, and it delivers unsurpassed output in the most challenging tailings dewatering conditions — without the need for flush water during operation.

The TDW series of pumps helps mining operations achieve sustainability goals with efficiency and the lowest total cost of ownership (TCO) available.

Tailings dewatering

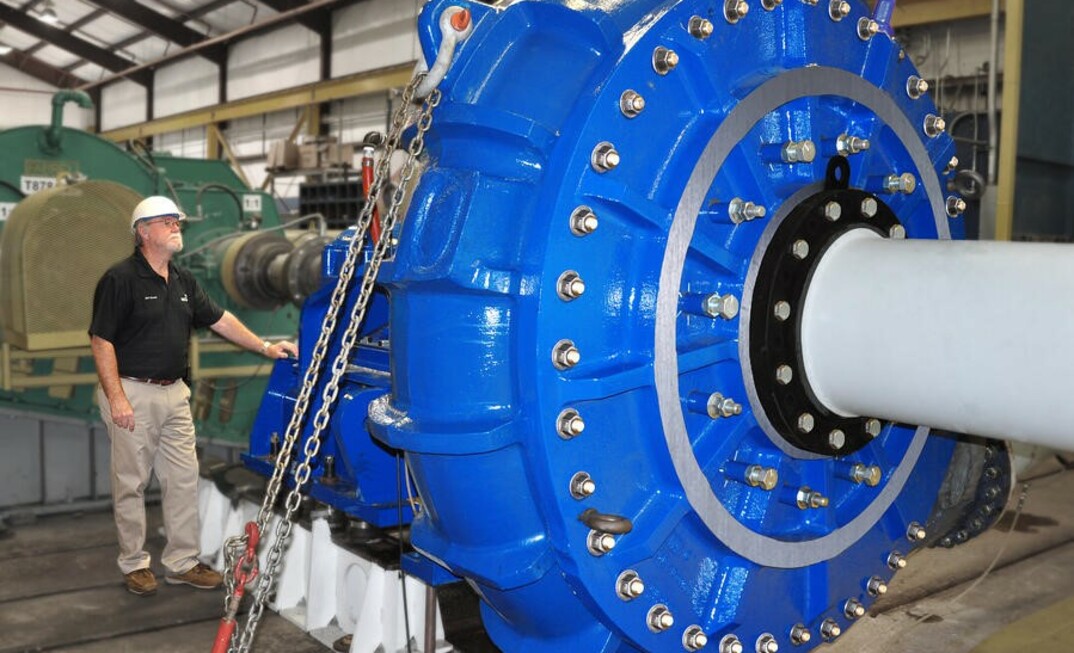

Reclamation of tailings ponds in mining frequently occurs in locations without easy access to usable gland water necessary for proper pump operation in tailings dewatering applications. Transporting water to these remote locations is cumbersome and costly. The TDW series was designed to provide a complete range of expeller pumps starting with the LCC expeller range which features up to a 28-inch impeller. The WBC-54 expeller, with its 54-inch impeller, was developed in response to increased demand for pumps with waterless seals. It has been successfully operating in the field since 2019. TDW pumps bridge the gap between the two and provide additional capability beyond the range of the WBC-54.

Meet the TDW

KSB's GIW® slurry pumps are designed to fit the needs identified through close working relationships with customers. The TDW series is particularly focused on improving efficiency, lowering TCO, and helping customers achieve their sustainability goals by eliminating the need to transport water to remote locations at mining sites.

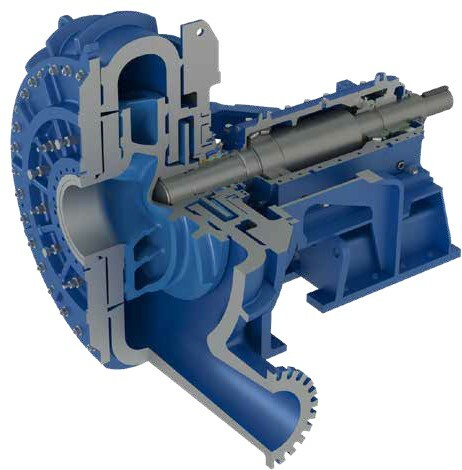

TDW pumps feature a fully integrated expeller shaft seal for flush free operation, an automatic, metered grease dispenser for timely, calibrated shaft seal lubrication, GIW's standard adjustable suction liner for optimal pump and expeller seal performance for the equipment's full life cycle, and plugged drains and flush ports in the expeller housing.

The TDW's high-head capable upsized shaft plug offers maximum reliability, and the series is manufactured with GIW's proprietary Gasite™ wear materials, including a 29G chrome white iron impeller for high-speed capability and maximum maintenance life. The balanced hydraulic design includes a four vane impeller that can achieve high developed head with low suction head, or even suction lift, while minimizing vibration, maximizing efficiency, and maintaining the TDW's capability to pass large solids.

Mechanical features for easier maintenance

Mechanical features standard to the TDW pump series include impeller release rings for quick impeller change outs and enhanced maintenance efficiency. The redesigned pedestal allows for easy access, reduces the pump's footprint, and includes lift points for full pump removal. Bearing arrangements are robust and configured for limited end float, and all hardware is fully metric to simplify tooling requirements.

ABOUT THIS COMPANY

GIW Industries

GIW delivers slurry transport solutions to your industry every day. Everything we do revolves around supporting you. Choose GIW today and you’ll gain a partner that’s dedicated to your success.

HEAD OFFICE:

- 5000 Wrightsboro Rd, Grovetown, GA, 30813, United States

- Phone: +1 706 863 1011

- Website: www.giwindustries.com

- Email: GIW-Marketing@ksb.com