Froth flotation stands as one of the most significant scientific and practical breakthroughs of the 20th century. This method remains the cornerstone of the mining industry for extracting valuable raw materials from ores. A prominent figure in this field is Professor Graeme Jameson, renowned for his extensive career and for inventing the Concorde Cell™ as an improved version of the earlier invention, the Jameson Cell.

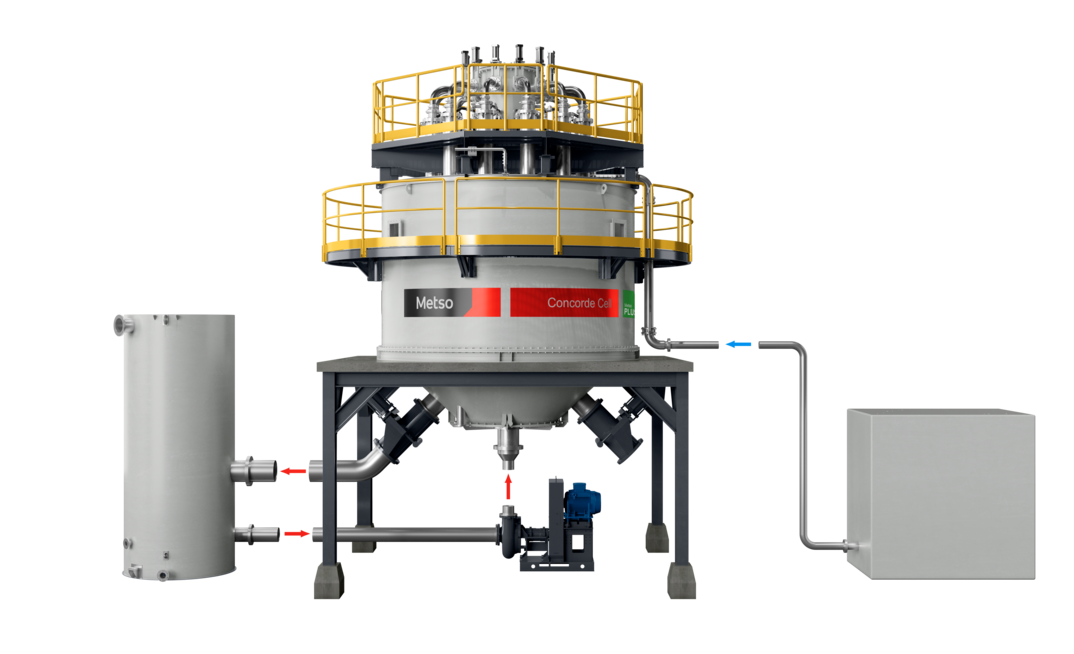

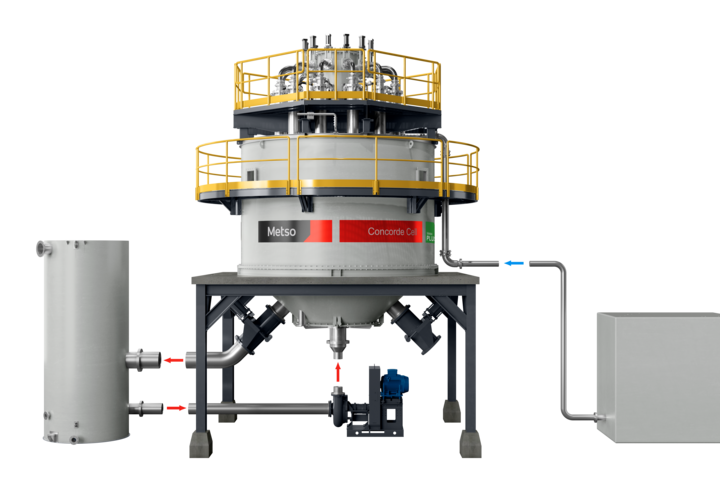

The Concorde Cell™ developed by Professor Jameson represents a significant breakthrough in ultrafine flotation technology. Now exclusively part of Metso's flotation portfolio, this technology continues to set the standard for performance and innovation. Building on the success of the Jameson Cell, the Concorde Cell™ has the capability to handle even finer mineral particles, those smaller than 20 microns.

We talked with Professor Graeme Jameson about his career, and his groundbreaking work in flotation technology. His contributions continue to shape the future of mineral processing and inspire advancements in the field.

Curiousity, connections and the wonder of bubbles

"I've always been curious about the natural world. I'm an experimentalist, and the longer you work, the more you've seen and the more cross links you can make. For the Concorde Cell™ , I got the idea from the oil industry while I was working there.

I started work in flotation when I was at Imperial College in London in the late 1960s. I became friends with Dr Joe Kitchener of the Royal School of Mines, who was a very well-known man in a field of flotation chemistry. He told me that in his opinion, the chemistry of flotation was well advanced, but the hydrodynamics of bubble-particle interactions was much less understood.

Joe started talking to me about bubbles. He said the mining industry was being transformed. High-grade deposits that had been discovered in the past were being worked out, and the head grades of new deposits were falling. The new ores had to be ground finer and finer in the mill to release the valuable particles. This was putting a strain on existing flotation equipment.

He knew I had a background in bubble and particle mechanics at Cambridge, and he encouraged me to start working on flotation, especially trying to explain why small particles are difficult to float. I worked on this with a couple of PhD students over some years and got ideas from that. I also received encouragement from people in the industry to keep working on my ideas.

We understood more about the problem from an academic point of view but then came the difficulty of putting this knowledge into practice. Our work suggested that we needed small bubbles, much smaller than found in conventional machines, to improve flotation kinetics of small particles. I began to think in practical terms, aiming to come up with a device that would be simple and cheap to build, would not require small holes and orifices that would block and would require very low maintenance.

At the same time my supervisor at Cambridge published a paper with a theory that could predict bubble sizes in a shearing flow. He developed an equation which related the size of the bubbles to shear rate, surface tension and other variables.

So, I looked at this paper and I thought I could devise something very simple that would make the bubble sizes that I wanted, which were quite small. I built a small prototype and looked for a way of testing it in operational conditions.

I had a grant from the Australian Minerals Industry Research Association (AMIRA) to measure bubble sizes in operating plants around Australia. This brought me into contact with technical staff at Mount Isa Mines (MIM) where there was an excellent team of research metallurgists who became interested in what I was doing. They arranged for me to work in the concentrator over the weekends to generate data, and I did that. The assay results were very good. So they took it on as a project and put on a recent graduate to spend a year addressing scale up possibilities with it.

And again, it came through with flying colors. So MIM decided to take it on as a product. And, after three to five years, the Jameson Cell really took off."

Experiments and supersonic flows – the Concorde Cell™

"I was thinking about what next to do in the field of flotation. It was well known that recovery of valuable minerals was a strong function of particle size. Mid-size particles, from 20 to 150 microns in diameter, were relatively easy to float with traditional devices, but ultrafines and coarse particles were more difficult.

Well, I said – we have something in the middle, which is the Jameson Cell. Now I will tackle the finer particles, the ultra-fine particles. At other end of the spectrum was the very big ones, approaching the size of fine beach sand, which I'd leave for another time.

I remembered my work in the oil industry in America immediately after my PhD graduation. They had difficulty in designing flow systems to extract residuals or "bottoms" out of vacuum distillation columns, handling high boiling point material that was essentially bitumen.

At low pressures, the bitumen was boiling as it was sucked out of the distillation columns, creating a two-phase choked flow, blocked by a shock wave. The velocity of the fluid coming out of this machine was quite high, but the pressure was very low, so the volume was enormous. The design problem was to relate the speed of sound in the two-phase system with the properties of the liquid bitumen, the volume of the gas and liquid phases and the operating pressure. There was no theory at the time, and no experimental evidence. It was an area that had not been investigated.

So, when I left that oil company and went to Imperial College London, I set up a project on the flow of a two-phase mixture of air bubbles and water as it passed through a venturi, where it was easy to reach the speed of sound in the throat, where the velocity was highest. Downstream of the throat the flow became supersonic. The apparatus was transparent so we could see what was happening."

Shockwaves and surfactants

"Now, we could see a standing shockwave, because there was a change in the opacity of the bubbly flow as it passed through the venturi. But we could not hear much, because the velocity was relatively low, and any sound generated by the bubbles was absorbed by the water.

The key was this: I added a surfactant to the water to make stable bubbles a bit like at home when you are doing the washing up with just an ordinary detergent.

And what I saw was amazing. Big bubbles in the flow before the shock wave broke into little bubbles as they passed through it. I realized that they were the right size of bubbles for flotation. I had the idea for the Concorde Cell™ .

By this time, I'd moved to the University of Newcastle in Australia, and I started an investigation into the Concorde, in which the liquid was a flotation feed, containing floatable mineral. The D80 of the feed particles was only 6µm. And we saw what we had hoped to see. We got much better performance than other devices with these tiny particles. I called the new technology the Concorde Cell™ , because supersonic velocities were achieved, as in the Concorde airplane.

Concorde Cell™ technology was introduced to the industry in peer reviewed articles in 2010. But it was not until 2016 that the Concorde Cell™ really got going. I discussed it with Prof. Kari Heiskanen who worked at Helsinki University of Technology, and had close links with Outotec, Metso's predecessor. We did some more test work, and then eventually, Outotec took it on as a product."

"I have been impressed with Outotec, now Metso, for a long time. They publish genuine scientific and research papers. The people I deal with are very competent in the basics – many of them have PhDs in mineral processing.

Metso is navigating the challenge of getting a new, groundbreaking technology introduced, and they are doing it in a good way. They are experienced people. They are not expecting things to happen overnight, but they are putting in resources and developing the market."

About Concorde Cell™

One of the key improvements of the Concorde Cell™ is its enhanced particle recovery. It excels at recovering ultrafine particles, which are increasingly important due to the complex mineralogy of lower-quality deposits. This is achieved using sonic shockwave technology, which brings bubbles and particles into contact more effectively, thereby improving the flotation kinetics and efficiency.

Additionally, the Concorde Cell™ generates smaller bubbles, resulting in higher gas holdup. This increases the bubble surface area, enhancing particle attachment and overall recovery rates. With the growing demand for raw materials driven by the green transition, Concorde Cell's ability to process complex ores is crucial. These advancements make the Concorde Cell™ a powerful tool for modern mining operations, ensuring efficient and effective mineral recovery.

Metso acquired the Concorde Cell™ license from the University of Newcastle in 2017. The development of commercial industrial scale units was fast-tracked, and full-size Concorde Cell™ units have now been in operation already for more than five years. Metso has exclusive rights to Concorde Cell™ technology.

About Professor Jameson

Professor Graeme Jameson, a Laureate Professor at the University of Newcastle, Australia, has made significant contributions to the field of mineral processing. He earned his Bachelor of Science degree in Chemical Engineering from the University of New South Wales in 1960 and his PhD from the University of Cambridge in 1963.

Throughout his illustrious career, Professor Jameson has been recognized with numerous accolades. In 2005, he was appointed an Officer of the Order of Australia for his services to engineering, science, industry, and the environment. In addition to this prestigious award, Professor Jameson was elected a Fellow of the Royal Society in 2018, joining a fellowship of the world's most eminent scientists. He has also been honored with the Prime Minister's Prize for Science in 2015, the Ian Wark Medal of the Australian Academy of Science, and the Gaudin Award of the US Society of Metallurgical Engineers.

Professor Jameson's groundbreaking work in flotation technology, particularly the invention of the Jameson Cell and the Concorde Cell™ , has had a profound impact on the mining industry, enabling the efficient recovery of valuable minerals from finely-ground ores.