Cooling such an environment presents a huge challenge – both financially and technically. In steps KTI Global Mining, a global leader in ice-making technologies, which has successfully designed, installed and commissioned a surface plate ice plant at Harmony’s Phakisa Gold Mine.

“We are the new kids on the block in underground mine cooling, and we really want to make sure we provide solutions that will tick all the boxes with regards to our clients’ requirements.”

These are the words of Joe van Wyk, newly appointed Chief Operating Officer of KTI Global Mining, a subsidiary of KTI, based in Balzheim, Germany. KTI has just launched two new products into the mining market, complementary to its surface plate ice plants.

“We have listened to our potential clients, as well as listened to leaders in the underground cooling space, and have come up with two new products that will change the way underground cooling will be looked at – the Underground Plate Ice Plant, and the Underground 1 Megawatt Water Chiller,” says Van Wyk.

KTI is globally regarded as the leader in concrete cooling. The company’s world-class engineering teams, and renowned German manufacturing standards, have ensured that KTI is regarded as the go-to guys in the concrete cooling domain since 1986. KTI can claim that it has been a key part of the construction of some of the most iconic building projects in the Middle East.

KTI ice plants are modular in their design and operation and this is one of the main reasons why Harmony’s Phakisa Gold Mine management in South Africa considered KTI as the solution to complement their existing underground cooling solution.

Cooling a deep one

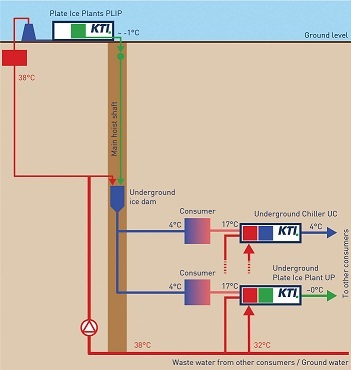

Phakisa Gold Mine looked for additional ice to supplement its 2,000 tons of ice per day surface ice plant that existed at the time. It used underground water chillers for bulk air cooling, and the surface ice plant to cool underground service water and for spot coolers.

The managers decided on KTI’s modular plate ice plant system. Initially, two ice plants with 200 tons of ice per day capacity each were constructed in Balzheim, Germany. These were then shipped to Cape Town as containerised systems, and against all odds, they were installed and operational within 10 days. Subsequently, another four containerised units were installed, and the KTI surface plate ice plant has been running 24/7 at a capacity of 1,200 tons of ice per day.

KTI’s surface plate ice plants are now complemented by the introduction of an underground version, with a production capacity of 80 tons of ice per day. These underground units are also manufactured in Balzheim, Germany, and are easily transportable and relocatable. They have been designed to fit easily down a mine shaft. The Underground Plate Ice Plants, or UP80’s, come in two modules – a refrigeration unit, and a plate ice unit. These units can be assembled in four different arrays, depending on the underground space available.

Mining, on a global scale, has continuously been challenged by three factors in recent history: cost saving, improved efficiency and environmental responsibility. As more and more ore deposits “open up” down at depth, through improved underground mining methods, a need for more innovative supporting processes, such as mine cooling, also increases.

Two main factors contribute to heat at depth in underground operations: the inherent geothermal gradient, or latent heat of the rock mass, as well as operational heat generation within stopes. Delivering an ambient working temperature is a prerequisite for any underground operation.

More chilled out

In addition to the Surface and Underground Plate Ice Plants on offer, KTI has also launched its new Underground 1 Megawatt Water Chiller – the UC1000.

KTI answered a need expressed by various potential customers, delivering a product that will solve many problems regarding getting “coolth” where it is needed most – the rock face. These units, just like the underground plate ice plants, are mobile – therefore easily relocatable to serve its purpose where needed as underground development progresses. Special care was taken in the design of the underground products, assuming high water fouling factors, robust and corrosion-free materials to handle the rough underground environment and the use of Freon – a human friendly refrigerant.

“Although it is not essential, the UC1000’s will work best in conjunction with our surface or underground ice plants”, says Van Wyk. “Water at around 17°C can be received by the UC1000 from a consumer, after the consumer has received 4°C water from an ice silo or dam. This 17°C water can then be brought back down again to 4°C by the UC1000 for final use by, for example, a cooling cart,” adds Van Wyk.

Mr Andreas Eyd, General Manager of KTI, makes a point of the effort his team has put in to come up with products that truly serve their purpose. “We have asked questions, and we have listened very carefully. I believe we have a suite of surface and underground cooling solutions that will change the way things have been done historically in this domain.

“One of the big advantages of KTI systems is their modularity in nature – you just add capacity as you go along – avoiding massive capital layouts at early stages of project development. One thing we will always be clear on: we will never compromise on materials and manufacturing process quality. This is even more applicable to the underground mining domain. We literally have people’s lives in our hands, and we will make sure they think of KTI as the coolest guys in mining!”

KTI-ce, ice, baby!KTI Global Mining’s surface and underground ice plants make use of the basic property of ice: due to its latent heat of fusion, or ability to absorb heat as it melts, a certain amount of ice absorbs much more heat than the same amount of water. To increase the temperature from 0 to 1°C, water absorbs 4.2kJ/kg. The same amount of water, as ice, absorbs 335kJ/kg to melt at 0°C. KTI Global Mining’s plate ice plants offer the following advantages: 1. KTI Plate Ice Plants deliver 0°C water underground. Conventional chilled water systems deliver 3 to 6°C water.

2. By using KTI Plate Ice Plants there is less water flow and up to 85% less pumping energy for waste water return needed, as well as improved performance of the heat exchangers. The cost saving on pumping is therefore dramatic. For a 15MW plant, the yearly energy saving exceeds 60,000,000kWh. For example, at $0.07/kWh, the yearly saving represents over $4 million. KTI’s underground plate ice plants have the added benefit of reducing or eliminating the use of turbines as well. 3. Ice, as the cooling medium, has a lower heat-loss factor than water, flowing from surface to the stope underground i.e. ice “holds its cold” far better than water. 4. The mass flow of water pumped up and down the mine is drastically reduced. It is proven that the mass flow of water can be reduced 5-8 times by introducing ice systems into the underground domain. 25,000 tons of 5°C water is required to fight a heat load of 15MW at 2,000m depth, versus only 3,200 tons of ice. 5. Underground silos or ice dams effectively store “coolth” underground, thus providing the most efficient way of satisfying variations in underground cooling demand. KTI offers Mobile Ice Storages to enable thermal storage and deliver ice only when needed.

6. The KTI surface and underground ice plants are modular and easy to install, thus delivering a scalable solution that can grow as the mining operations expands. This reduces the initial need for large capital expenditure for a surface or underground plate ice plant.

|

KTI-Plersch Kältetechnik GmbH Carl-Otto-Weg 14/2 D-88481 Balzheim Germany T: +49 7347 9572-0 F: +49 7347 9572-22

E-mail: mining@kti-plersch.com