Minerals processing is changing. Depleting ore grades and rising energy costs set new challenges for the mining industry. The pertinent question is if your selection of new solutions are based on innovative and energy efficient technologies and are they bringing a step change in your business operations!

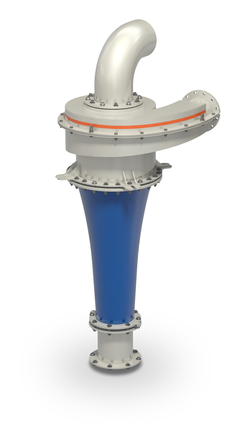

Automation, data mining and new technologies promise to maximize production output, reduce operating costs, and increase sustainability over the next few years. Metso responds to diverse needs by introducing the new MHC™ Series Hydrocyclone which provides a wide range of grinding circuit classification duties, ensuring maximum uptime and recovery to the customers. Designed to optimize mining applications, the new MHC™ Series represents the next generation of hydrocyclones. Tested rigorously in the field with successful results, the product offers significant advantages over previously available technologies. Metso's new range focuses on enhanced process performance, superior wear component design, and improved ease of maintenance.

Advanced design for increased capacity and accurate distribution

The internal geometry of the MHC series has been developed to promote smooth flow of the material from the inlet into the hydrocyclone, minimizing liner wear and increasing throughput. The unique single component conical section eliminates the need for multiple conical section housing and liner parts, thereby increasing wear life and keeping downtime to a minimum. Metso's improved manifold design ensures accurate feed distribution including overflow and underflow collection from multiple hydrocyclones operating in parallel.

Broad product line offering

The new product improves Metso's existing equipment offering, which now covers the supply of entire grinding circuit systems to our customers. The MHC™ Series is available in seven different sizes with diameter ranging from 100 mm to 800 mm. Each size has a range of vortex finder and apex inserts to fine tune the classification performance.

Promising results

The story of innovation and efficiency continues through the entire Metso process equipment line. Our world-class wet fine classification technologies help to increase efficiency, capacity and profitability in customer operations. This next generation technology will surely allow the mineral processing industry to reach new heights.

Discover more> http://www.metso.com/products/separation/MHC-hydrocyclones/

Know your contacts:

• Thierry Monredon, Global Manager, Flotation

thierry.monredon@metso.com

• Ben Klein, Global Product Manager, Hydrocyclones

ben.klein@metso.com