In an industry where uptime, safety, and efficiency define success, mining operations are turning to innovative partners to stay competitive. ME Elecmetal, a global leader in wear solutions and optimization services, is helping mines achieve just that—through advanced mill and crusher technologies, digital tools, and a commitment to continuous improvement.

We sat down with Alvaro Braun, Vice President of Commercial – North America, to discuss how ME Elecmetal is reshaping grinding and crushing performance, enhancing safety, and delivering measurable results for customers across the region.

Integral Solutions

Interviewer: Alvaro, ME Elecmetal has been a global name in mining solutions for over a century. What sets your approach apart when it comes to mill and crusher optimization?

Alvaro Braun: At ME Elecmetal, The Continuous Improvement Process is our foundation. We engineer mill liners, grinding media, and crusher wear parts with the goal of maximizing performance, minimizing downtime, and ensuring the lowest total cost of ownership for our customers. What sets us apart is that we don't just supply products— we deliver fully integrated solutions by partnering closely with our customers to tailor solutions for their specific needs and continually improving them over time.

Mill Liners

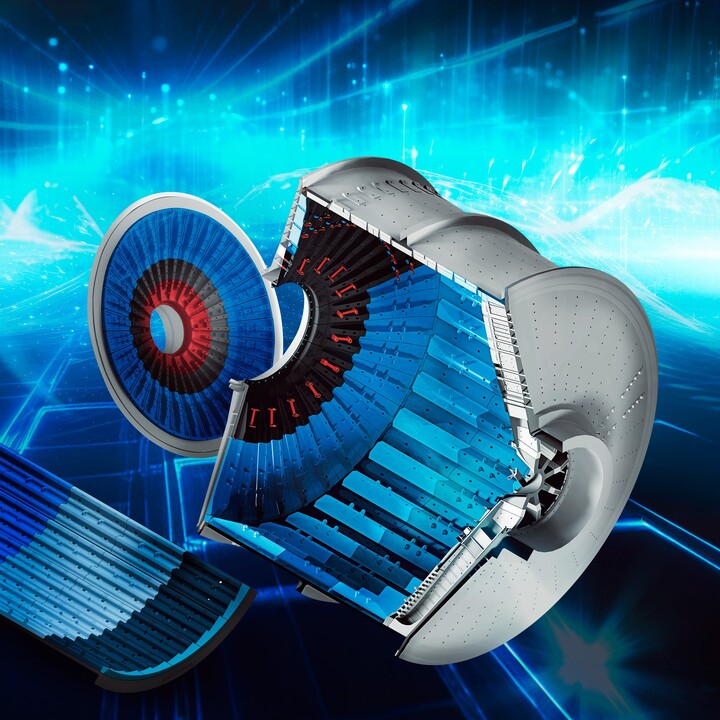

Interviewer: Let's start with mill liners. How is ME Elecmetal pushing performance forward in this area?

Alvaro Braun: Our high-performance grinding mill liners are designed using advanced materials, precise engineering using the latest modeling technology, and leveraging the strength of our global installation database and know-how. We closely evaluate each site's operating conditions, listen carefully to our customer's needs, and develop a tailored liner system to help end users meet—or exceed—key performance targets which typically include throughput, efficiency, uptime, and safety.

One example is our ME PolyFIT® hybrid liners, which combine abrasion-resistant rubber with our market-leading steels and white irons. In the right application, they deliver all the benefits of a casting while enabling faster, safer installation thanks to fewer components and lighter weight. This is a game-changer for operations looking to boost mill availability and throughput, while also reducing noise levels and total liner weight.

Grinding Media

Interviewer: And what about grinding media? How are you supporting customers in that area?

Alvaro Braun: We're a global leader in forged steel grinding media, and what makes us different is our collaborative approach. Our application engineers partner with customers to fine-tune media consumption, improve charging practices, and increase throughput. We don't just ship product—we support the entire lifecycle with analytics and performance tracking.

Because we have large-scale global manufacturing capacity and a strong global supply chain, we can provide consistent, prompt deliveries while adapting solutions as the operation changes over time.

Crusher Wear Solutions

Interviewer: What about the crushing side—how are you improving uptime and safety there?

Alvaro Braun: We supply high-performance crusher wear solutions for primary, secondary, and tertiary applications—engineered to optimize both throughput and wear life. We pay close attention to overall crusher performance, ensuring our liners maximize the available power of the machine—regardless of crusher brand, model, or application.

We offer a portfolio of over ten different manganese-bearing steel alloys to meet the demands of the toughest and most aggressive crushing applications. Every design is built for reliability, quick changeouts, and a seamless fit with existing equipment, helping our customers maintain uptime, reduce risk, and keep production on track.

We also put safety front and center with our Crusher Safety Tooling, helping maintenance teams work safer, faster, and more efficiently. It's about protecting people while keeping the plant running at peak performance and minimizing downtime.

Advanced Optimization Tools

Interviewer: ME Elecmetal has introduced several digital tools. How are these helping customers make smarter decisions?

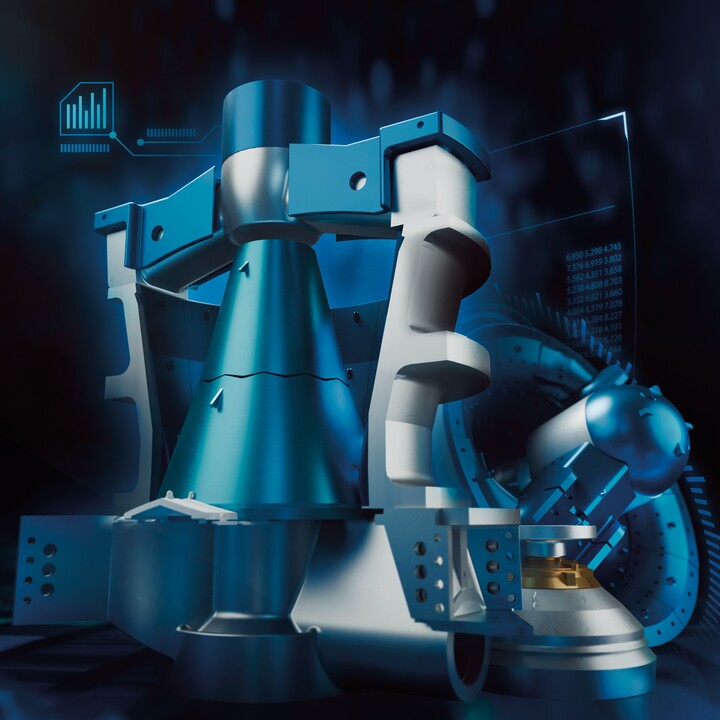

Alvaro Braun: Digital innovation is a big focus for us. Our QuickScan™ systems—for both crushers and SAG mills—provide fast, remote, and accurate scans. For example:

Our QuickScan™ Crusher is a remote-controlled robotic scanning system that captures precise visuals of primary crushers without manual cleaning or entry—improving safety and speed.

Then there's QuickScan™ Grinding, which scans a full SAG mill in about 15 minutes without anyone stepping inside. That's a big safety and productivity win.

We also offer 3D Laser Scanning and Wear & Performance Tracking, giving customers real-time visibility into asset condition and wear trends.

Interviewer: How fast can customers expect to see results?

Alvaro Braun: That's a key advantage. We provide preliminary wear reports within two hours, and full, detailed reports in two business days. It's about speed, accuracy, and actionable insights.

Interviewer: You've also introduced some interesting fastening technology. How does ME SecureFIT® change the game?

Alvaro Braun: ME SecureFIT® External Bolting eliminates the need for personnel to enter the mill during liner installation, which greatly improves safety and reduces downtime. This technology is available not only with our ME PolyFIT® products but also with our traditional cast liners, making it an industry game-changer. By reducing human-machine interaction and streamlining installation, we're helping customers achieve faster changeouts without sacrificing performance or reliability.

We've taken it further with our ME SecureFIT® Smart Bolting System (SBS) — this uses sensorized bolts to monitor tension in real time, enabling predictive maintenance and helping avoid failures before they happen. It's ideal for mills and other critical equipment.

Sustainability and Global Reach

Interviewer: Sustainability is top-of-mind for many mining companies. What role does ME Elecmetal play in this space?

Alvaro Braun: Sustainability is built into everything we do. Our cast liners are 100% recyclable, and we've developed processes to recover scrap grinding balls and remanufacture key components. We're also helping customers reduce their environmental footprint by increasing equipment efficiency and reducing waste.

Interviewer: Finally, with such a global footprint, how do you support customers in different regions?

Alvaro Braun: We have ten metallurgical plants worldwide and operations in over 40 countries. That means we can provide localized service with global expertise, ensuring fast delivery and consistent quality no matter where our customers operate. Our goal is to be not just a supplier, but a long-term partner in operational success.

Inerviewer: Where can mining professionals learn more or connect with ME Elecmetal in person?

Alvaro Braun: We'll be at the 2025 Convención Internacional de Minería in Acapulco, November 19–22, at Booth #6111. It's a great chance to meet face-to-face, explore our latest technologies, and discuss how we can help optimize operations. You can also visit our website at www.me-elecmetal.com or call us at +1 480-730-7500.

Closing Note from Alvaro Braun: "As mines push for higher availability with lower risk, ME Elecmetal's wear solutions and optimization tools keep performance trending up. Ready to turn incremental gains into lasting advantage? Let's talk."

ABOUT THIS COMPANY

ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mining industry. Renowned for its commitment to innovation and technology, ME Elecmetal is dedicated to delivering cutting-edge sustainable solutions that exceed customer expectations worldwide.

With a broad range of products and services, including grinding media, mill liners, crusher liners, and large specialty castings, ME Elecmetal is the preferred partner for crusher operators and mineral processors seeking to optimize their processes.

The company operates state-of-the-art metallurgical plants strategically located across Chile, the United States, Peru, China, South Africa, Indonesia, and Zambia. With a robust manufacturing capacity exceeding 134,000 tons for foundry products and 600,000 tons for grinding media, the company continues to meet the growing demands of the mining industry.

ME Elecmetal’s commercial presence extends to over 40 countries, solidifying its position as a global leader in delivering innovative solutions to the mining sector.

Learn more about ME Elecmetal’s global footprint and commitment to excellence in integral solutions at www.me-elecmetal.com.

United States Offices

- 4500 S Lakeshore Drive, Tempe, AZ 85282, United States – Tel: 480-730-7500

- 3901 University Ave NE, Minneapolis, MN 55421, United States – Tel: 763-788-1651

- Email: marketing@meglobal.com

- Website: www.me-elecmetal.com